Value Stream Mapping Quizlet Chapter 7. Value Stream Mapping is a powerful technique that allows us to create a "BIG PICTURE" visual representation of To assist the organization in moving from large-batch, push production to one-piece, pull flow through the entire value stream. A qualitative lean tool for eliminating waste that involves a current state drawing, a future state drawing and an implementation plan.

Profitable Applications of Lean Value Stream Mapping.

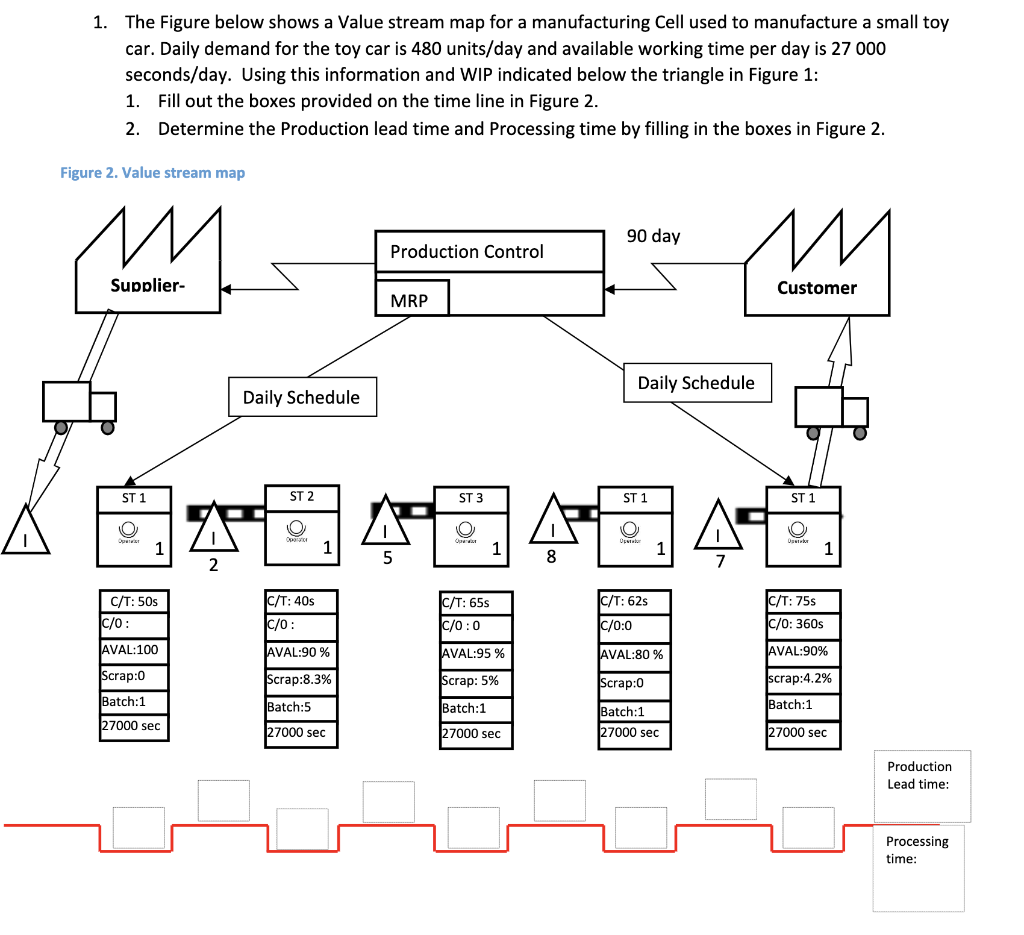

What is value stream mapping (VSM) used for? to depict and evaluate the current and future state of the material and information flow of manufacturing processes of a.

A qualitative lean tool for eliminating waste that involves a current state drawing, a future state drawing and an implementation plan. The Value stream mapping process allows you to create a detailed visualization of all steps in your work process. The original VSM template was created by Toyota Motor Company and implemented via material and process flowcharts.